Project Overview

The Helium Recovery Project addressed a critical cost challenge across a 38-laboratory research facility where helium scarcity had driven operational costs to $34 million annually. Each of the 38 separate scientific laboratories used helium for different research purposes, with each room operating under different experimental requirements and schedules that could not be interrupted.

Complex Technical Requirements

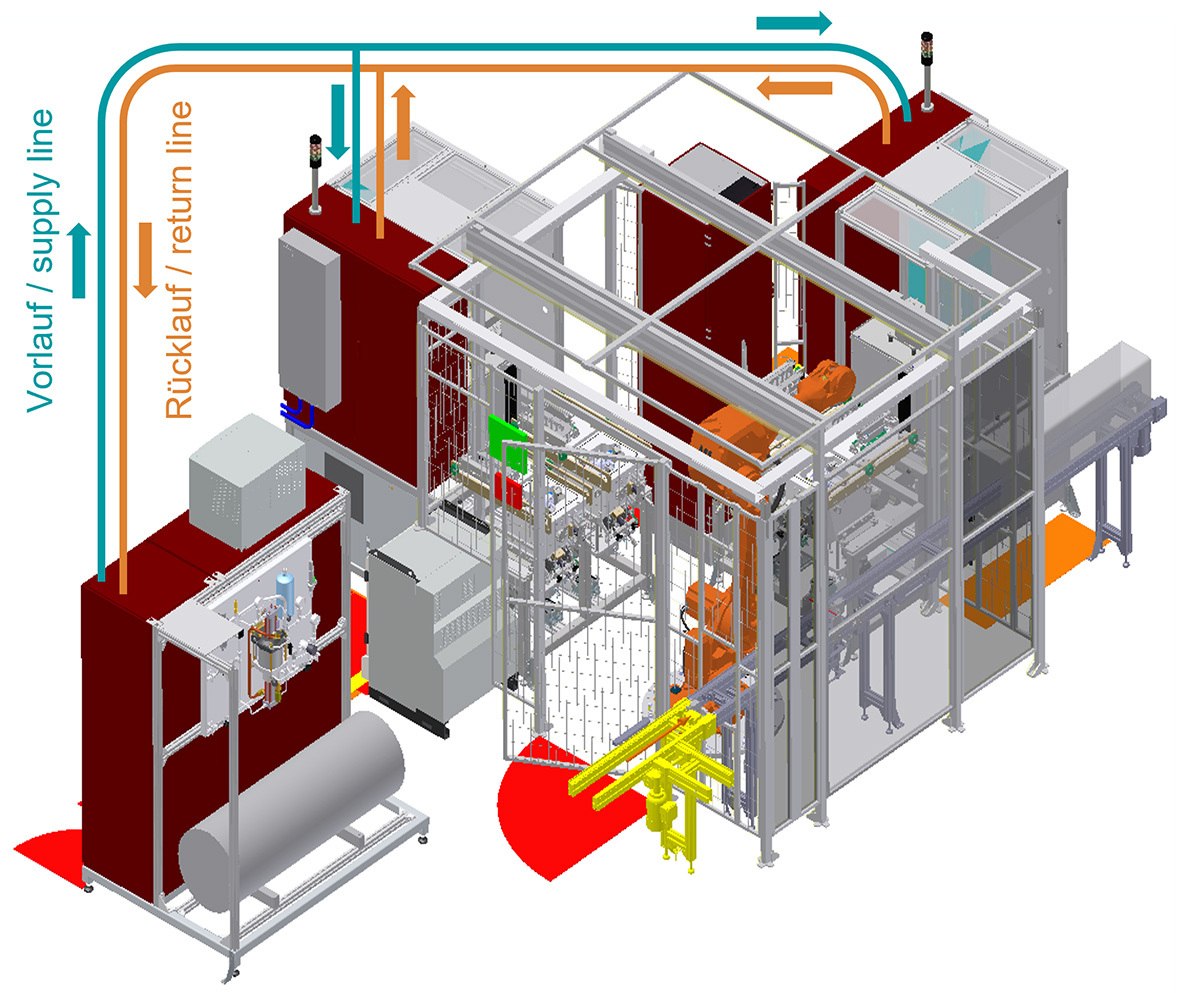

MTI designed, built, and installed a complete helium recovery system throughout the building, creating a capturing mechanism in each laboratory that transported recovered helium to a centralized mechanical room. The complex system converts helium from gas to liquid state, recaptures the gas, returns it to the mechanical room, and converts it back to liquid for proper storage and redistribution throughout the building.

Coordination & Installation Challenges

This innovative system eliminated the need for individual tank ordering and movement, instead delivering helium to one central location for distribution through the building, recovery after use, and reuse in a continuous cycle. The project required coordination with 38 different laboratory owners, each with unique safety precautions, equipment requirements, and experimental schedules that demanded individual coordination for access and installation.

Project Results

Result: Working in active facilities that could not be disturbed or taken offline, MTI successfully installed all complex piping and systems while maintaining ongoing research operations. The project achieved remarkable results, reducing annual helium costs from $34 million to $2 million, delivering $32 million in annual savings while ensuring uninterrupted research capabilities.